You can find the Interactive Hall Plan 2024 here.

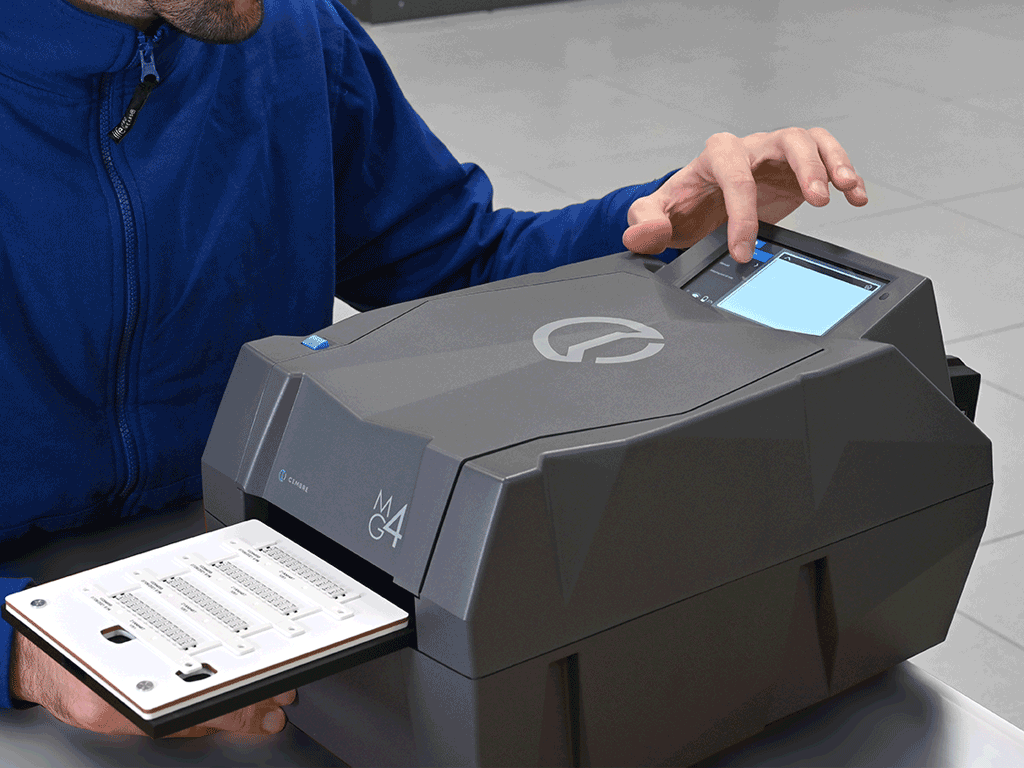

18.0 V Cordless Hydraulic Crimping Tool B600CND

Description

Crimping force kN 60

B600CND is a new generation of hand-held cordless tools, characterised by a “Bilinear” mechanical design.

Equipped with a Smart Release system which automatically retracts the ram at the end of the operating cycle.

B600CND is suitable for crimping electrical connectors onto conductor cross sections up to 300 mm², using its own range of semicircular 60 kN die sets.

Equipped with Li-Ion 18.0V - 2.0Ah rechargeable high capacity batteries.

The OLED display provides essential real time operating data, including:

- generated crimping force thus verifying accordance with best practice

- battery charge status

- general operating information

- the number of work cycles completed and remaining before recommended maintenance.

The tool is supplied as:

- Basic tool with battery and wrist strap

- Spare battery

- Battery charger

- USB cable

- Plastic carrying case suitable for storing the tool and accessories

The new Generation of battery operated hydraulic tools

The new generation of handheld cordless hydraulic tools heralding a significantly advantageous evolution from past models.

- Design & Comfort

- Ergonomic Design

Features:

- “Bilinear” mechanical design

- Smart Release system to automatically retract the ram at the end of the crimping cycle

- Electronic Pressure Sensor (EPS)

- SMARTOOL technology for viewing and downloading operational data

Bilinear Structure

Operator comfort and convenience are key factors in producing repeatedly consistent high integrity crimped joints.

Cembre ‘nd’ bilinear tools are designed mechanical centre of gravity nearest to the operator’s wrist to optimise the overall ergonomics of the tool and provide a wider support for the hand.

Thus the innovative misalignment between the pump drive mechanism and the hydraulic system both reduce the torque generated on the operator’s wrist and best distribute the stresses acting on the hand.

Smart Release Technology

“Smart Release Technology” is a new development by Cembre comprising an intelligent oil pressure release system which stops the motor at the end of the crimping cycle.

Automatic retraction of the ram only occurs when the operator releases the start button, this allows visual verification of the jaws to ensure that they have fully met prior to releasing.

Similar tools with ‘standard’ automatic return do not permit this visual verification that full compression has taken place before releasing pressure.

Electronic Pressure Sensor

The EPS guarantees the precision of the crimping operation, checking the actual value of pressure and informing the operator of possible errors.

SMARTOOL Technology

SMARTOOL technology enables the user to to store data from up to 200,000 cycles on the integrated memory card for transfer to a computer via a USB cable.

Discover more from us