You can find the Interactive Hall Plan 2024 here.

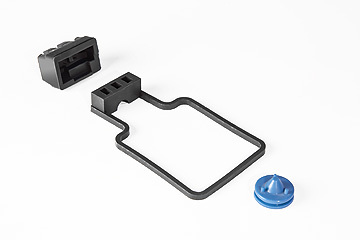

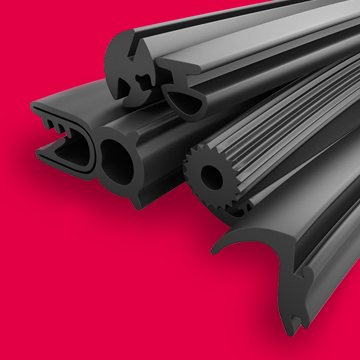

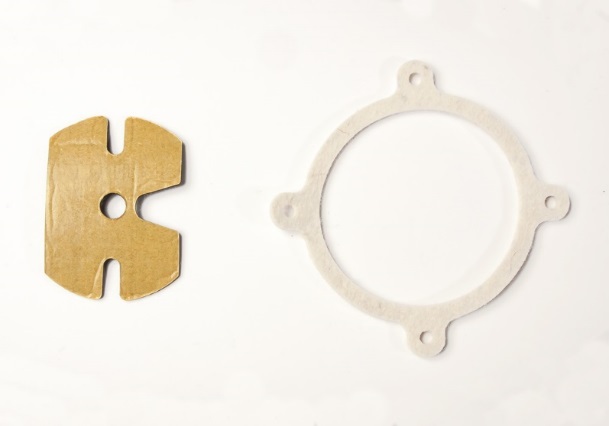

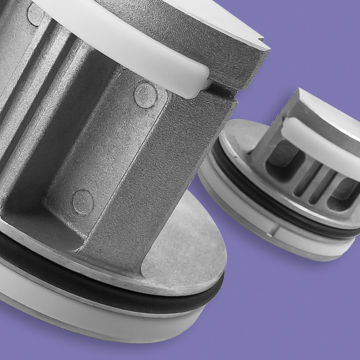

MOULDED ITEMS

Description

INJECTION moulding is carried out through horizontal and / or vertical presses. The raw compound is loaded, raised to the right temperature, and then injected into a metal mould where it is cured for a predetermined time. This procedure is particularly suitable for manufacturing large series of technical products and o-rings.

COMPRESSION moulding always takes place in a metal mould, the raw compound is loaded manually. This process is suitable for producing smaller quantities of large sized and heavy items.

Tolerances allowed for injection and compression moulded parts: ISO 3302-1 class M2. O-Rings: ISO 3601-1.

Address

DRS Guarnizioni Industriali S.r.l.

Via Consolare 75

25030 Erbusco Brescia

Italy

Telephone+39 030 726 7592

Fax+39 030 776 8849

Discover more from us